Guaranteeing patient safety means ensuring the reliability and quality of increasingly controlled products. This is the major challenge to be met by bar-turning in the medical industry.

DECOREC supports you in the bar-turning of your precision mechanical parts for non-implantable medical devices.

Why work with DECOREC?

You would like to:

- Increase performance AND optimise the technical and economic aspects of your products.

- Innovate AND reduce the development time of your products.

- Optimise and reduce the size of your products WITHOUT any loss in efficiency.

Work together with DECOREC

It’s the promise to:

- achieve one shot design thanks to our global approach.

45 years of industrial performance. - Build up longterm constructive partnerships with our clients and suppliers.

82 % of our clients have been with us for over 10 years. - guarantee the conformity and quality of your products thanks to the reliability of the whole of our process.

Only 5 customer claims per year, all clients included, for 15 million parts delivered. - Partnership with a company able to deliver internationally.

45 % of turnover for the export market.

Our support in medical bar-turning

Whether for new projects or series production, our support includes several phases:

- Design or design improvement

- Manufacturing: bar-turning, grinding

- Finishing operations: sand-blasting, shot-peening, sorting

- Assembly

- Supply chain

Discuss together your projects in medical bar-turning

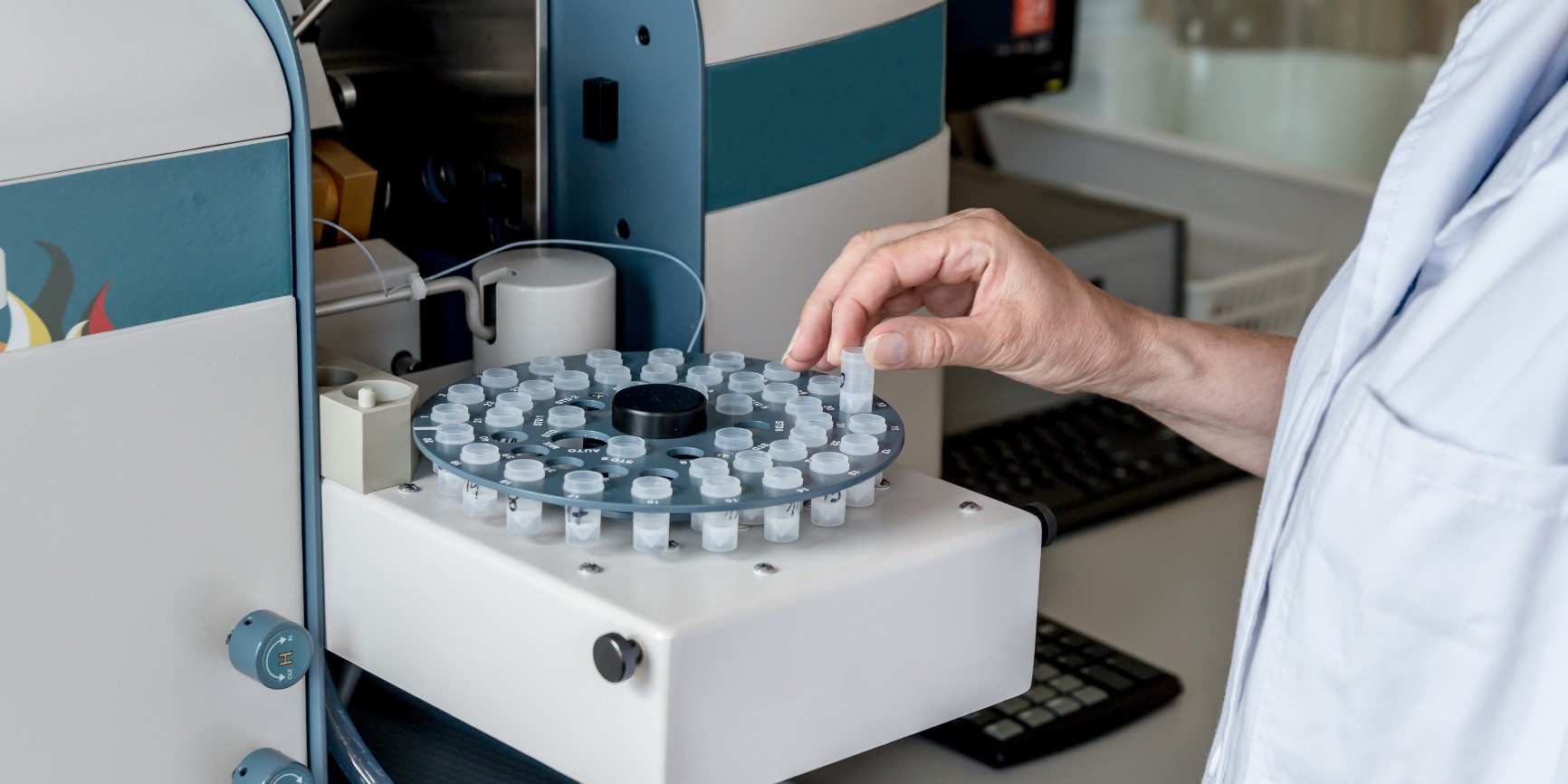

Our control of the complete value chain allows us to improve our responsiveness and ensure better cost control. We respect the criteria of cleanliness thanks to our high-performance equipment: specific cleaning machines, particles extractor and scanner. We have inspection and measuring devices to ensure the conformity of the parts.

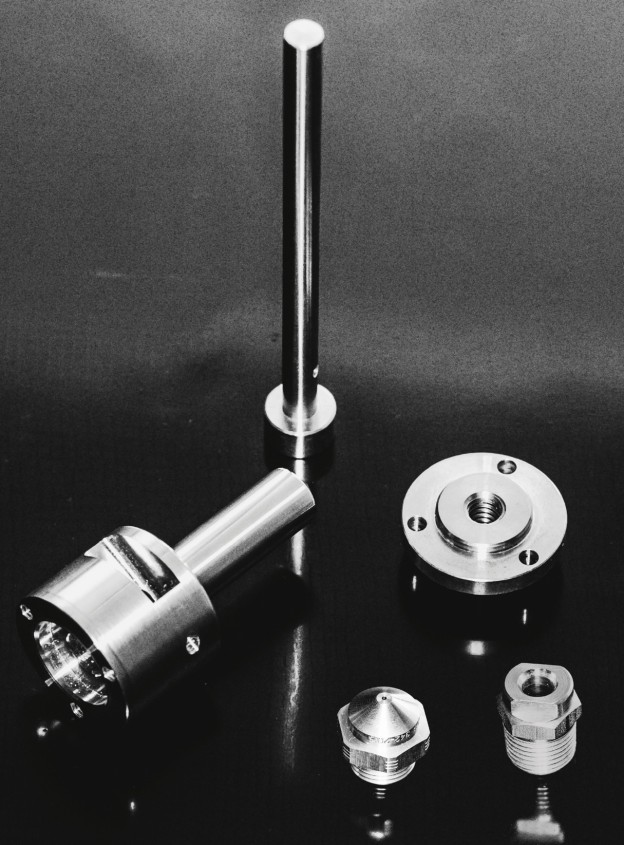

Discover our parts for the medical industry:

- Pistons

- Pins

- Connectors for the spraying sector (pharmaceutical industry)

Some specifications:

- Materials: Steel (1.4404, 1.4104…), brass, lead-free brass

- Working diameter tolerance +/- 3 µm

- Roughness (Ra <0.2)

- Boring (+/-0.05 mm)

- Series size: 250 to 5,000 parts

Case study

Our customer designs, manufactures and integrates dosing pumps for the medical sector.